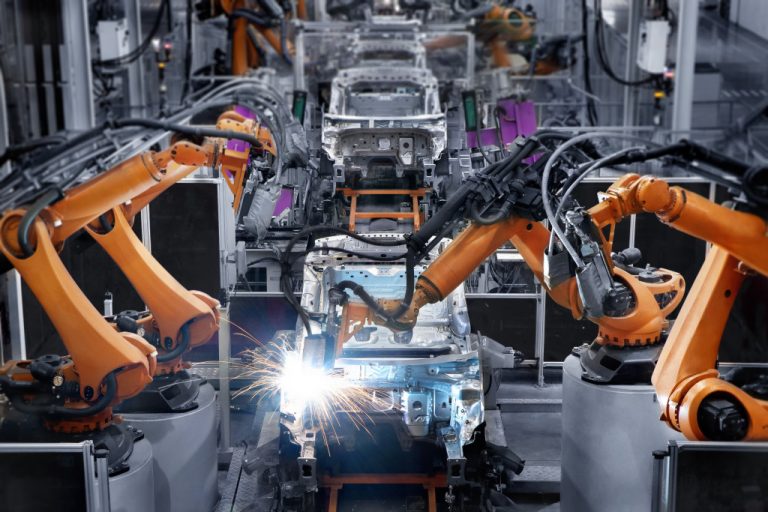

Manufacturing facilities are among the most accident-prone industries due to employees operating heavy machinery. Machinery can be hazardous if not used properly and can easily cause an accident if not handled with caution. To ensure employees’ safety and avoid accidents, it is essential to follow all safety procedures when working with machinery. These include wearing the correct safety gear, being aware of your surroundings, and following all safety instructions. If everyone in the manufacturing facility follows these safety precautions, it can help reduce the number of accidents in this industry.

Accidents in manufacturing facilities can often be severe. One of the most common accidents is when an employee gets struck by machinery. That can often result in serious injuries or even death. Another common accident is when a chemical or other hazardous material injures an employee. These types of accidents can often cause long-term health problems for the employee. Finally, slips and falls are common in manufacturing facilities and can often result in serious injuries.

While these accidents are common and scary in nature, there are ways that they can prevent them from happening. Here are some of the ways to do just that:

Keep Floors Clean and Clear

One of the best ways to prevent slips and falls is to keep the floors clean and free of debris. That includes mopping up spills, sweeping floors, and removing any obstacles that could cause someone to trip.

Most manufacturing facilities with heavy machinery use oil in their operations and processes. And one of the most common reasons why slips and falls occur is oil spilling onto the floor. Oil is a stubborn substance, and it can be challenging to clean it up and altogether remove it from your facility’s floor. An excellent way to remove them is by using a nano sponge that absorbs oil more than water.

Another common reason slips and falls happen is that obstacles and debris obstruct the pathways in a manufacturing facility. It can lead to workers tripping over equipment and injuring themselves.

Keeping your floors clean and clear of any obstructions is vital in any manufacturing facility. Doing so will help you keep your employees safe and secure while maintaining manufacturing production.

Machinery Training

Another way to keep employees safe in a manufacturing facility is by providing adequate training on operating all the different machines they’ll use. Employees need to be aware of the dangers of operating heavy machinery and be taught how to use it safely. Training employees on how to use machinery can help prevent accidents in your facility.

It’s also essential to keep up with the training as new machines get introduced into the manufacturing process. As technology advances, so do the dangers of using those machines. Employees need to be up-to-date on the latest safety procedures when working with these machines. Having that new

If you provide adequate training and keep up with it as new technologies get introduced, you can help keep your employees safe while they work.

Personal Protective Equipment

When working with hazardous materials and chemicals, wearing the proper personal protective equipment (PPE) is essential. PPE includes items such as gloves, goggles, and respirators. Wearing PPE can help protect you from harmful chemicals and other dangers in the manufacturing process.

It’s also essential to ensure that employees get the appropriate training on using PPEs If they don’t know how to use it properly, it can do more harm than good. Ensure that your employees know when they need to wear their PPEs and how to put them on properly.

Chemicals and Hazardous Substances

If your manufacturing facility uses a lot of chemicals and hazardous substances, it’s essential to keep them properly stored and managed. That way, you can avoid long-term health problems for your employees.

Hazardous materials and chemicals can be dangerous if not handled properly. They can cause serious health problems for employees exposed to them regularly.

It’s essential to keep these substances in safe containers and storage areas. That way, they’re not easily accessible to employees, and they won’t accidentally come into contact with them.

It’s also essential to have proper ventilation in the areas where these substances get kept. That will help reduce the risk of any harmful fumes getting inhaled by employees.

If you use and store hazardous materials and chemicals in your manufacturing facility, it’s essential to take safety precautions. You can help protect your employees from long-term health problems by doing so.

Maintaining safety in a manufacturing facility can be challenging, but taking the necessary precautions is essential. One of the most effective ways to keep employees safe is by providing adequate training on using machinery safely. You should also ensure that your floors are clean and clear of any obstructions and that employees are wearing personal protective equipment when needed. Additionally, you need to keep hazardous materials and chemicals adequately stored and managed to avoid long-term health problems for your employees. You can help maintain a safe working environment in your manufacturing facility by following these tips.