The packaging line is among the basic but most important components of a factory. If your line moves slowly, it would affect production, which would affect profitability. Improving packaging speed saves money and time, which should be taken careful consideration when making packaging line reforms. Understand that approaching this process blindly can mean inconveniences and unplanned expenses. Below are ways to improve packaging line efficiency.

Train Your Employees

Well-trained employees are more productive. If you are yet to train yours, it is advisable to do so immediately. It is true that training might slow down production. However, this delay will only be temporary. Additionally, the advantages of taking your workers away for training would outweigh the disadvantages. Be careful to offer relevant training. For instance, you should train them on how to handle the specific types of equipment you have. If possible, discourage job switches, especially if your employees cannot handle each equipment piece.

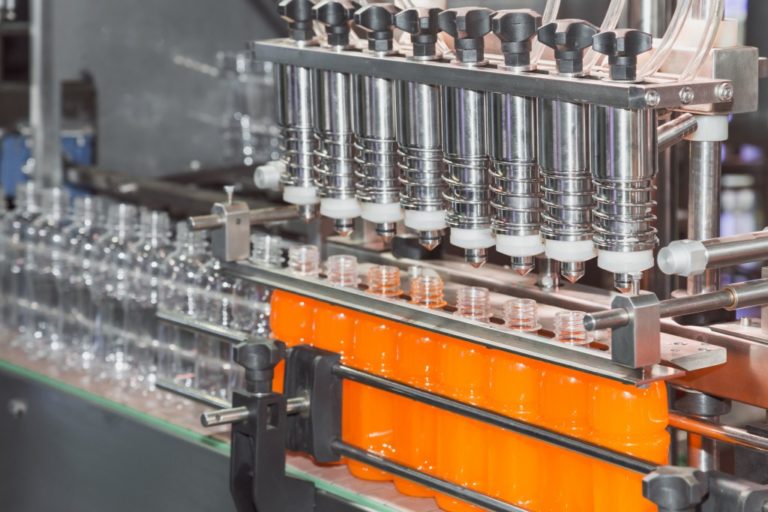

Invest in Proper Packaging Machinery

Most of the time, the machines used to package products are the main culprits behind slow down production lines. If your machines are outdated, it is advisable to upgrade them. It is true that it could affect your budget, but new, highly effective machines would minimize unexpected costs in other areas. Most importantly, they would increase productivity, which translates in profitability. Understand that only the right filling and packaging equipment would be value for money. This makes it important to research well before contacting any packaging or filling machine manufacturer.

Identify Time-Consuming Areas

Investing in modern machinery would not mean much if they do not address time-consuming aspects of your assembly line. Before making drastic changes, make a list of slowdown spots. You should monitor the line carefully for several days to identify all spots creating bottlenecks. If you identify many areas, it is advisable to focus on one spot at a time. This helps avoid heavy expenses and other inconveniences. It is important to avoid quick fixes.

Reduce Package Touches

The more package touches there are, the higher the damage risk. When the damage rate is high, packaging line efficiency becomes low. You should take measures to minimize this damage whether your business has constantly fluctuating production and sales volumes or not. It is true that manual labor can be cheaper where there is a high fluctuation regarding production volumes. However, it increases the chances of accidental damage, especially where there are many touches. It is advisable that you do not keep your machines idle in favor of manual labor.

Create Productivity Goals

Giving your staff goals helps keep productivity predictable. If they know what they are working towards, it would ensure that they work hard throughout to achieve those goals. Consider introducing a graduated goals plan. If they reach one goal, they should set their sights to the next one. A system of goals ensures that your staff would always be moving towards improvement.

Your employees play a primary role in improving packaging line efficiency. Training them and giving them goals would not mean much if they are not motivated. You should boost employee morale by offering incentives, rewards, and providing a good working environment.