Setting up a manufacturing plant is a huge investment, and there are many things to consider before making a decision. Here are some of the most important factors to think about:

Location

Location is one of the most important factors to consider when setting up a manufacturing plant. The right location can help you save money on infrastructure and labor costs, making it easier to find qualified workers.

It’s essential to choose a location accessible to your customers and suppliers and has the infrastructure you need to run your plant.

Taxes and Regulations

Businesses need to understand the tax and regulatory environment in the location they are considering for their manufacturing plant. This will help them determine the feasibility of setting up a manufacturing plant in that location and the costs associated with doing so. It is also important to be aware of any changes to the tax and regulatory environment after setting up the plant.

Some things to consider when assessing the tax and regulatory environment are:

- The corporate income tax rate

- The sales tax rate

- The property tax rate

- The business license tax rate

- Environmental regulations

- Labour laws

- Health and safety regulations

Labor Costs

When setting up a manufacturing plant, it is essential to consider labor costs. Labor costs can be a significant portion of a company’s expenses and can impact the profitability of the plant. It is important to find a location with a low cost of living to keep labor costs as low as possible.

The company should also hire workers willing to work for a lower wage. Additionally, companies can seek out unions and other labor organizations to help keep labor costs under control. By taking into account labor costs, companies can ensure that their manufacturing plants are as profitable as possible.

Manufacturing Capacity

One of the most important decisions you’ll make when setting up a manufacturing plant is how much production capacity to build. You’ll need to take into account the type of products you plan to make, the demand for those products, your current and projected production costs, and how much space and equipment you have available.

Another important consideration is whether you plan to produce products in-house or outsource them. Outsourcing can be less expensive in the short term, but it can also limit your production capacity and increase your costs in the long run.

Working with an industrial equipment supplier, such as Americas Industrial Supply, will also ensure the company has a ready supply of tools and equipment for the business.

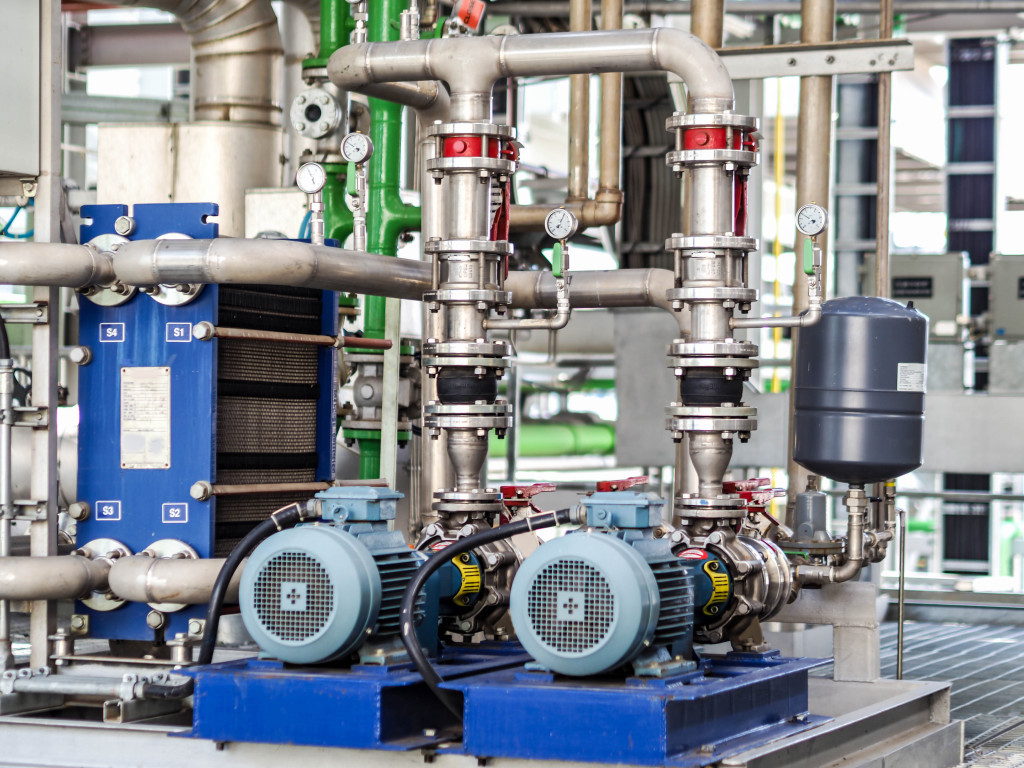

Infrastructure and Utilities

Manufacturing plants require a lot of power and water. Ensure that the infrastructure is in place to support your plant before setting it up. You will also need to consider things like waste management and environmental regulations.

When establishing a manufacturing plant, it is important to consider the infrastructure and utilities needed. For example, you will need to have a reliable source of electricity and water. You may also need to have a wastewater treatment facility on site.

Additionally, you will need to consider the transportation needs of your plant. You will need to have adequate transportation infrastructure to move your products to and from the plant.

It is also important to have a good communication infrastructure in place. You will need to be able to communicate with your suppliers and customers easily. A good telecommunications infrastructure can help you do this.

Finally, you will need to have a good security infrastructure in place. You will need to protect your plant from theft and vandalism. A good security system can help you do this.

Access to Markets

Access to markets is an important consideration for companies when deciding to set up a manufacturing plant. Manufacturing plants need to be close to their customers to minimize shipping costs and maximize customer service. Plants also need to be located where they can take advantage of the available resources, such as labor and materials.

Quality Control and Standards

It is important to have suitable quality control and production standards in place when setting up a manufacturing plant. This will ensure that the products produced are of the highest quality and meet customer expectations.

It may be necessary to invest in sophisticated quality control equipment to maintain high-quality standards. The company should also hire experienced staff who are familiar with how to use this equipment. In addition, it is important to establish clear and concise manufacturing standards that all staff is expected to adhere to.

This can help to ensure that products are consistently produced to the same high standard, regardless of which member of staff is producing them. It can also help to identify and correct any problems with quality before they become too serious.

Setting up a manufacturing plant is no small feat. It takes careful consideration and planning to ensure it’s effective, profitable, sustainable, and meets the needs of customers and stakeholders alike.